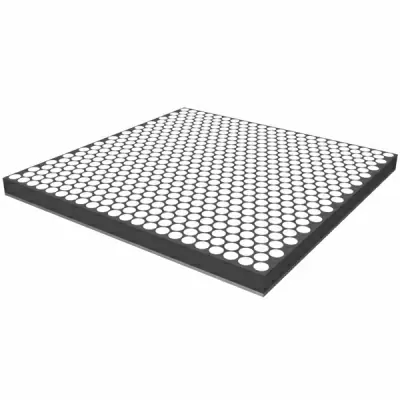

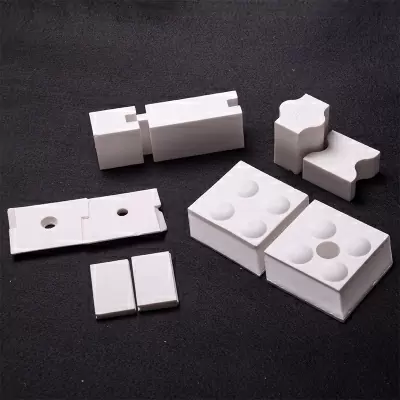

Also named wear ceramic parts,wear rubber ceramic plate,wear resistant ceramic pads

Ceramic rubber composite pads&plate is use of rubber vulcanization process, to embed the wear-resistant ceramic vulcanized into rubber,stick it on the inner all of equipment with the adhesive paste. As customers’ requirement,it also can be vulcanized together with steel plate,with bolts or not.

Category | 92 Series | 95 Series | T 95 Series | 99 Series |

Al2O3 | ≥92% | ≥95% | ≥ 95% | ≥ 99% |

Fe2O3 | ≤0.25 | ≤0.15 | ≤0.15 | ≤0.1 |

Density | >3.60g/cm3 | >3.65g/cm3 | >3.70g/cm3 | >3.80g/cm3 |

HV Hardness N/mm2(MPa) | 980 | 1040 | 1100 | 1250 |

Bending Strength MPa | 260 | 280 | 320 | 350 |

Compressive strength MPa | 1150 | 1200 | 1250 | 1300 |

Fracture Toughness MPam 1/2 | 3.68 | 3.72 | 3.94 | 4.5 |

Jet impingement abrasion | ≤0.47/cm3 | ≤0.42cm3 | ≤0.28/cm3 | ≤0.10/cm3 |

Features:

It combines wear-resistance of ceramic and impact-resistance of rubber,apply to conveying systems equipment work under normal temperature,and can bear some impact.

Applications:

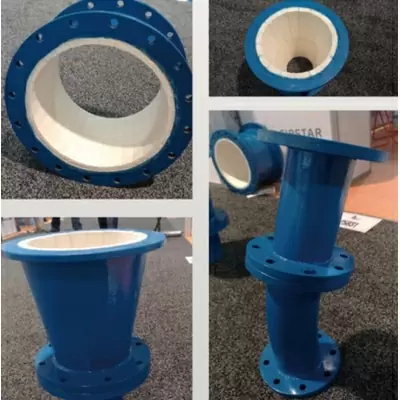

Pads and plates have been designed primarily for the lining of high wear components in mining and mineral processing equipment including:

Pipes and tanks

Chutes

Hoppers

Launders

Mill feed components