ALUMINAS

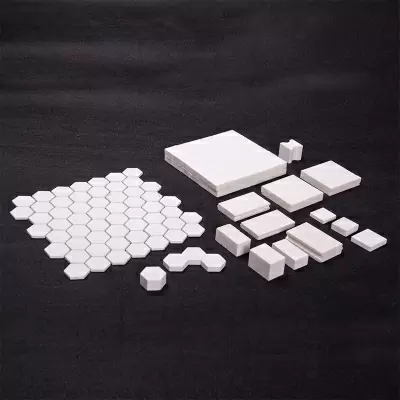

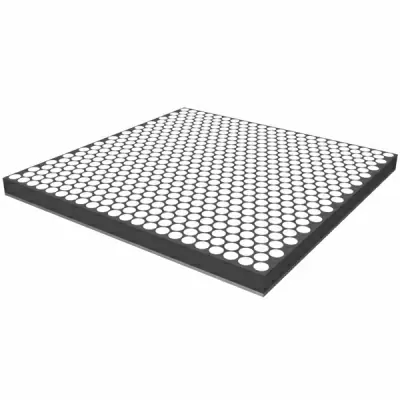

Used in heavy industry for years as a cost-effective, wear-resistant solution, these lightweight materials offer high durability, strength, and excellent abrasion and corrosion resistance. Alumina wear resistant compositions include:

· Alumina 90: most common wear product with great wear resistance

· Alumina 92: increased wear performance

· Alumina 96: premium alumina for best wear resistance

· Zirconium toughened alumina: increased strength and impact resistance

Advanced ceramic wear components for a variety of applications:

Processing equipment:

· Pharmaceutical clean rooms

· Food processing plants

· Grain handling

· Mineral processing

· Cement manufacturing

· Chemical processing

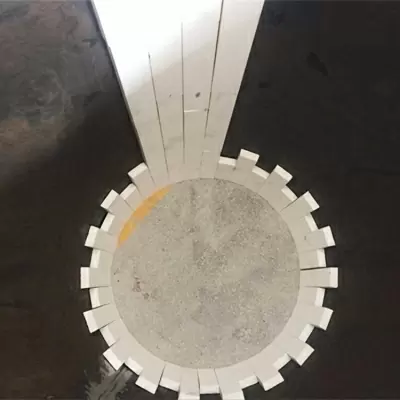

· Large Cyclones:

o Coal-fired power plants

o Steel Mills

o Asphalt Plants

o Petrochemical plants

· Pulp and paper mills

Category | 92 Series | 95 Series | T 95 Series | 99 Series |

Al2O3 | ≥92% | ≥95% | ≥ 95% | ≥ 99% |

Fe2O3 | ≤0.25 | ≤0.15 | ≤0.15 | ≤0.1 |

Density | >3.60g/cm3 | >3.65g/cm3 | >3.70g/cm3 | >3.80g/cm3 |

HV Hardness N/mm2(MPa) | 980 | 1040 | 1100 | 1250 |

Bending Strength MPa | 260 | 280 | 320 | 350 |

Compression strength MPa | 1150 | 1200 | 1250 | 1300 |

Fracture Toughness MPam 1/2 | 3.68 | 3.72 | 3.94 | 4.5 |

Jetimpingement abrasion | ≤0.47cm3 | ≤0.42cm3 | ≤0.28cm3 | ≤0.10cm3 |